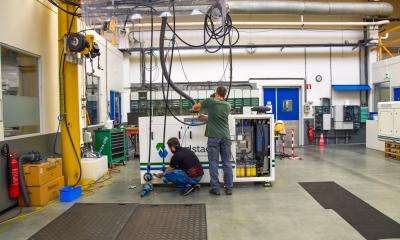

Advanced optical BPP verification at Nedstack

Today, most characterization techniques are cost-intensive and time consuming. In R&D electrochemical, potentiostatic or galvanostatic measurements are done which usually give information about just a small area of the fuel cell component. Inspection of a single cell within a stack or the whole fuel cell stack is very time consuming. However, regarding fuel cell mass production there is not enough time for a 100 % in-line inspection of all bipolar plates.

Optical 2-D and 3-D measurement technologies have the potential to offer high speed measurements with high accuracy characterization. But the correlations between optical surface parameters (accuracy geometry, defects etc.) and the performance of the individual components respectively their impact on the performance of the whole fuel cell system is not understood / correlated sufficiently, so that they can be applied for quality inspection in fuel cell production.

Check out the project video at:

https://www.youtube.com/watch?v=8XA5lZvHRvA&feature=youtu.be