At Nedstack we aim at optimizing the lifetime of our PEM Stacks and further reducing the footprint by pursuing the following targets:

- Continuously improve stack life to refurbishment;

- Continuously improve refurbishability (refurbishment cycles per stack life);

- Continuously improve the recyclability of the materials used (closed loop recycling);

- Contribute to the development of new recycling strategies and best practices;

Our current catalyst recycling concept still assumes pyro-metallurgical processing. However, we contribute to the development of new recycling concepts (i.e. selective electrochemical dissolution) as novel ways of recuperating valuable fuel cell commodities.

In this process we thankfully cooperate with the good people of the HyTechCycling project (http://hytechcycling.eu/). Their website comes as a strong recommendation to any inidividual interested in recycling of fuel cell components.

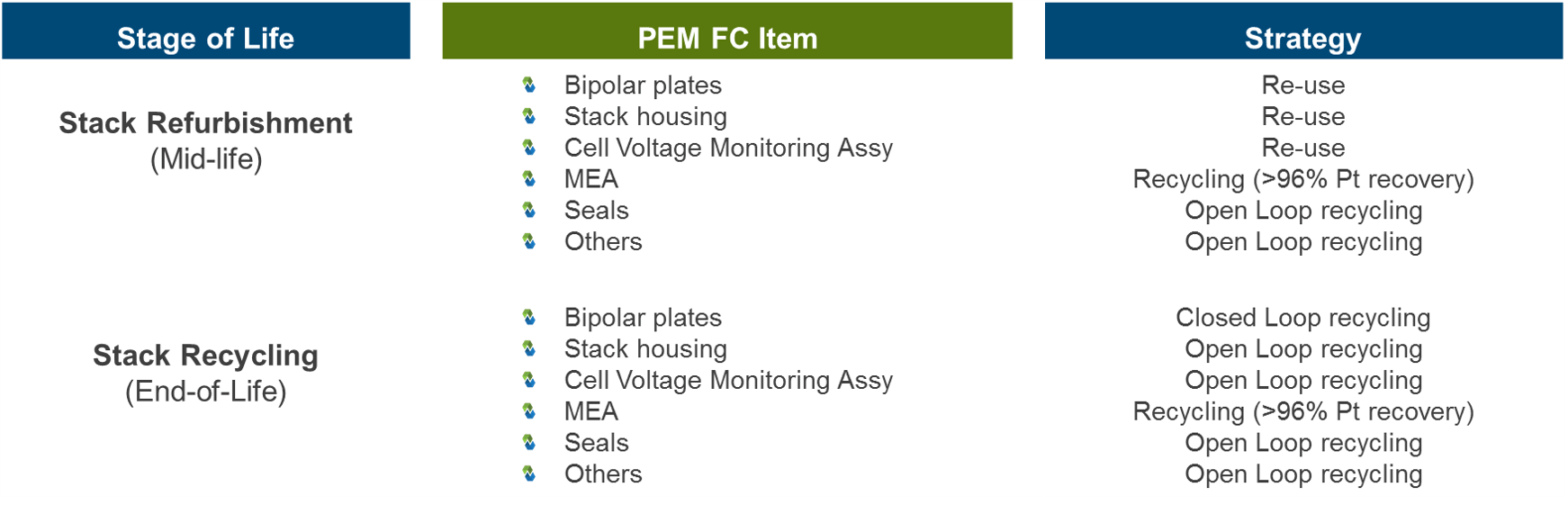

Below you can find an impression of our current Recycling & Refurbishment Menu. Prior to recylcing we process the following sequence:

- Collect stacks at our PemCare-Hub;

- Conduct a visual inspection and IV-curve measurement;

- Non-destructive stack dis-assembly;

- Manual sorting;

- Parts re-usability inspection;