The GRASSHOPPER (GRid ASsiSting modular HydrOgen Pem PowER plant) project was officially kicked-off on the 9th and 10th January at the Akzo Nobel facilities located in Delfzijl, where the demonstration phase of the project will take place. All the consortium partners, the members of the Advisory Board and the Project and Financial officers from the Fuel Cells and Hydrogen Joint Undertaking attended the event. At the kick-off the next steps for the first period were discussed, as well as the final demonstration.

INEA will coordinate the Grasshopper project, 36 months in length and a total budget of 4.4 M€, creating the next generation fuel cell power plants and demonstrating the flexible operation for grid support. The power plant uses green hydrogen and converts this into electricity and heat without emissions. With the variations in demand and consumption of energy from renewable sources such as sun and wind, a stable energy supply will rely more and more on flexible operation power plants.

The consortium consists, apart from INEA-Informatizacija Energetika Avtomatizacija, of Abengoa Innovación, S.A., Johnson Matthey Fuel Cells Limited (JMFC), Nedstack fuel cell technology, Politecnico di Milano (Polimi) and Zentrum für Brennstoffzellen Technik Gmbh (ZBT).

The Advisory Board, consisting of members from Akzo Nobel Industrial Chemicals B.V, Tennet TSO B.V, SWW Wunsiedel and members of GOFLEX consortium, will be consulted during the project phase.

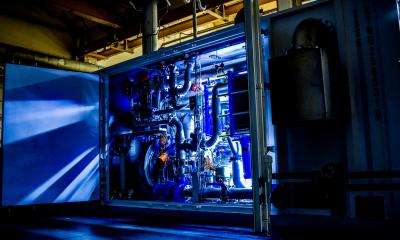

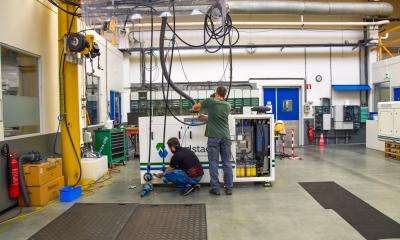

The innovative MEAs (membrane electrode assembly), stacks and fuel cell system will be developed through modelling, experiments and industrial experience by JMFC, ZBT and Nedstack. Abengoa Innovación will lead the design, construction and testing of a pilot plant. Polimi will provide support in the decision-making process through modelling activities and optimization. Implementation of the smart grid functionality into the FCPP control and grid integration will be done by INEA.

The demonstration unit will be installed in Delfzijl, where Akzo Nobel and Nedstack have been testing the fuel cell technology for over 10 years now, connecting to the hydrogen by-product stream of the modern chlorine production facility.

This project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking under grant agreement No 779430. This Joint Undertaking receives support from the European Union’s Horizon 2020 research and innovation programme, Hydrogen Europe and Hydrogen Europe research.

For more information, you can visit http://www.fch.europa.eu/project/grid-assisting-modular-hydrogen-pem-power-plant

Nedstack is a Dutch independent and one of the world’s leading, fuel cell manufacturer, producing Proton Exchange Membrane (PEM) fuel cells for heavy duty transport and for stationary applications such as PEM power plants and telecom backup. Founded in 1999 as a spin-off of Akzo Nobel, Nedstack has been able to deploy significant numbers of PEM fuel cell stacks in the world, gaining extensive experience on PEM fuel cell operation for different applications. Nedstack has demonstrated very long lifetimes and high efficiencies of their products.