EM fuel cell technology is more than a futuristic concept, says Jogchum Bruinsma, application manager maritime systems at PEM fuel cell producer Nedstack. “This is not just an idea anymore; PEM fuel cell-powered ships are already being built.” He is referring to the inland shipping vessels Maas and Antonie, which will be fitted with fuel cell technology by Nedstack “This shows the potential of fuel cells. Of course, these vessels will have limitations, however they will be able to perform the daily work for which they have a contract – without emissions and using today’s technologies.”

Bruinsma’s work at Nedstack looks further than the inland shipping sector for PEM fuel cell use. “PEM fuel cells are truly zero-emissions and there are so many possibilities. Zero-emission harbour tugs, for example, or larger applications such as offshore wind installation vessels; when they are in field, they do not consume that much energy, all that offshore installation work could be zero-emissions, only requiring fossil fuels for transiting back and forth to shore. These applications can be realized today, using existing technology. Another example is the auxiliary power and port navigation of a cruise ship, you are talking about megawatts running 24/7; this is also possible with our PEM fuel cells.”

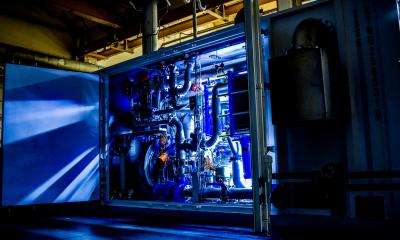

Industrial FC systems

Nedstack has an established track record with PEM fuel cell technologies. In 2007, the company built the world’s first PEM fuel cell power plant, which is still operational today. “The world’s largest PEMFC power plant was also built by us, so you could say that we are a market leader in industrial fuel cell technology.”

A significant feature of Nedstack’s PEM fuel cell technology is their capacity, as Bruinsma explains: “Our systems are high-power mission-critical industrial systems. This is different to smaller systems used in the automotive industry; these are intended to last up to 10,000 hours of operational lifetime. If you put that on board a vessel, in some cases it is just over a year of operation. We have a different approach – building fuel cell stacks to last for over 24,000 hours, and systems that will last for over 15 years. If you look at an inland shipping vessel running at about 4,000 hours per year, this is six years, before stack maintenance.”

How does a fuel cell work?

A Proton Exchange Membrane (PEM) fuel cell consists of a membrane in between two cell plates containing gas channels. On one side of the membrane is hydrogen. The hydrogen reacts with a catalyst in the membrane, which splits it into protons and electrons. The protons pass through the membrane. The flow of remaining electrons becomes an electrical current. On the other side of the membrane is air. The oxygen in the air reacts with the protons and electrons to form pure water. This can be summarised with the following equation: 2H2 + O2 = 2H2O + electricity + heat.

“One fuel cell can produce about 250 amps but at a very low voltage,” explains Bruinsma. “By stacking the fuel cells in series, we can create up to 13 kW in a single and modular stack. We can connect these units to make whatever configuration is needed. For example, we have 40kW, 100kW and 500kW systems.” This modularity yields important benefits to users: it means that they can interconnect units, scaling up or down as required, and when a fuel cell stack comes to the end of its lifecycle, it can be easily replaced. Another advantage of PEM fuel cells is their operating temperature. “We operate at 60 degrees, which is much lower than the 600 to 900 degrees required for a solid oxide fuel cell (SOFC). This means that we take only about 2 minutes to start up, and we can react to dynamic responses. An operating temperature of 60 degrees is also ideal for heating accommodation and storage holds.”

Software and hardware support

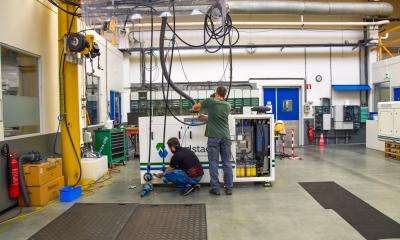

Nedstack’s current involvement in the maritime market is backed up by hardware and software support from Bachmann electronics. Similar to Nedstack’s modular and scalable setups, Bachmann offers a modular software structure that Nedstack use to build their system software one time right in a very efficient way. “Bachmann’s hardware systems are also flexible and reliable,” adds Bruinsma. “This gives us maximum control of what is happening in our systems. The integrated HMI is another great asset, and with the scope function, we can look at very detailed loggings without any additional measuring equipment.”

Grey and blue, but aiming for green

While it is generally assumed that hydrogen will play a major role in future fuel supply chains, the current situation regarding its production cannot yet be called fully sustainable. This is because a large amount of hydrogen is produced steam-methane reforming of natural gas. This is known as grey hydrogen, something that is still very much connected to fossil fuels and their associated carbon emissions. The next step is blue hydrogen, which is also produced from natural gas – the big difference is that the CO2 emission problem is solved by Carbon Capture and Storage. Electrolysis using electricity from renewable sources such as wind and solar power is the way to produce hydrogen with zero carbon emissions; this is green hydrogen.

For Nedstack, the type of hydrogen used is not relevant at this moment in time. “It is important to get started. With blue hydrogen or, worst case, grey hydrogen; because then at least in the production of power there will be no emissions,” says Bruinsma. “It is comparable our electricity supply – of course we want it all to be green, but we have to start somewhere.”

What the future holds

This begs the question of what he sees being the key milestones in the future. “Adoption is a major milestone – demonstrating that this technology is possible with commercially operated vessels. However, on-board hydrogen storage is a big challenge. Hydrogen is very energy dense in terms of weight, but not in terms of volume as it is a gas. Compressed hydrogen would be suitable for short sea and inland shipping, the next step being liquefied hydrogen for higher power and greater range.”

The next two milestones of mass production and cost reduction are closely connected: “This new market enables us as manufacturers to start investing in future developments and mass production. Once there is mass production, significant cost reduction will follow. This is something that will also happen with the hydrogen supply. In fact, I think that in five years’ time we will be having a very different conversation.”